Fire Barriers vs. FIRELOCK® Vaults

There is a critical difference between a fire barrier and an insulated structure. A frying pan on a gas burner does not allow the flame to penetrate the surface of the pan, yet the heat is conducted through the thin barrier very efficiently. The same principle applies to data-rated vault designs. That is why building a “vault” out of thin fire-stopping material with little insulating value has distinct limitations. Some products base their performance on temperatures taken at various distances from the surface of their vault structure. They do not publish the temperatures on the surface of their structure. How many storage facilities have so much room they can afford to waste what would otherwise be revenue-generating space? And what happens if some flammable material is accidentally placed against the wall of this structure, such as a cardboard box, when a fire strikes? That is not an experiment you want to conduct at your facility. And even if this buffer zone between the vault structure and the materials stored inside is maintained, the rate of temperature rise for these materials is beyond what is acceptable to achieve a data rating comparable to FIRELOCK® vaults.

Media Protection Vert Poster Sm

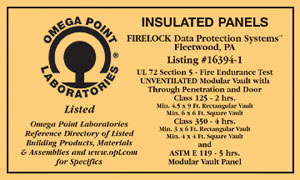

FIRELOCK® vaults are Laboratory Listed UL tested with Label and Certification

In order to meet the U.L. 72 Class 125 standard, your vault must be able to maintain temperatures below the critical threshold ON THE SURFACE of the vault interior. This is because in the real world you can’t count on a buffer zone between the vault structure and the materials stored inside. The Class 125 rating is recognized as the most stringent fire protection standard for data backup media in the world, and it is this standard FIRELOCK® uses to test and rate its vaults.

This standard does not just apply to the walls and roof (and insulated floor if the vault is above grade) of the vault; it applies to every component of the vault system. The old axiom, “a chain is only as strong as its weakest link,” is the methodology FIRELOCK® employs when building these vaults for mission-critical applications. Let’s compare FIRELOCK® components to other manufacturers:

VAULT STRUCTURE The walls and roof of our vaults are constructed with prefabricated panels with a core of ceramic fiber. This insulating material is typically used in high-temperature industrial applications, such as steel-manufacturing and other furnaces. These panels are custom-sized for each individual vault project to meet the exact size requirements of the client. Other manufacturers use materials that may be able to stop flames from penetrating the structure for a while but have limited heat-insulating capabilities.

VAULT DOORS The door used on a media vault is a major component, and perhaps the easiest way to spot a weakness in a vault that claims to have a Class 125 rating. Because there is no single door that provides a true Class 125 rating, a double-door assembly is required for media and server vaults. Without this outer-door and inner-door arrangement, a Class 125 rating is not possible.

AUTOMATIC DOOR CLOSERS In compliance with fire protection standards NFPA 232 and NFPA 75, every FIRELOCK® vault is equipped with automatic door closers to ensure the vault will be sealed in the event of a fire. The outer door closer is activated if it detects heat, smoke, flammable gas, or a power failure. This door closer can also be linked to the facility’s alarm system so the doors will close if a physical security threat is detected. The inner door closer is linked to the automatic closer on the outer door so they close in unison. Of course, if someone is inside the vault when the closers are activated, they can always get out since the locks are set up so you can’t be locked in. Once the personnel are out of the vault, the door closers will re-close the doors.

CABLE PENETRATIONS Contrary to competitors who use commercially-available fire-stopping materials around cable entry points into the vault, which are typically two-inches thick or less, FIRELOCK® installs a proprietary cable penetration assembly, or “cable tray,” for bringing power and data cables into the vault. These cable trays use ceramic-fiber insulation, heat-reactive expanding caulking, and PVC conduit, to ensure that heat and smoke cannot penetrate this barrier, even in a catastrophic fire.

HVAC PENETRATIONS Climate control is just as critical to the long-term survival of data on magnetic media as fire protection, so an effective HVAC system must be installed in any data vault to provide the optimum environment. But how do you bring ducted air into a vault chamber without compromising the integrity of the vault? FIRELOCK® is the only manufacturer to address this important issue. With a three-stage damper assembly within a protective steel housing filled with ceramic-fiber insulation, this proprietary design allows ducted air to be circulated through the vault chamber while maintaining the Class 125 rating.

As seen by the monumental loss of documents and data tapes in a fire at a major offsite storage firm’s facility in England, this type of fire barrier material may not even keep flames from spreading. This illustrates very clearly how a non-combustible structure does not equal a data-rated media vault. Using this type of material as a protective chamber for fragile magnetic media — aside from the lack of specialized components listed above — is a risk most organizations cannot afford to take. As the volume of information stored on data tapes and other backup media continues to increase, so too does the value of each media unit. Investing in a vault design with limited performance capabilities is an investment wasted. To effectively mitigate risk, you need a comprehensive data-rated vault design with a proven track record and documented test performance. These qualities are found only in FIRELOCK® Class 125 modular vaults.